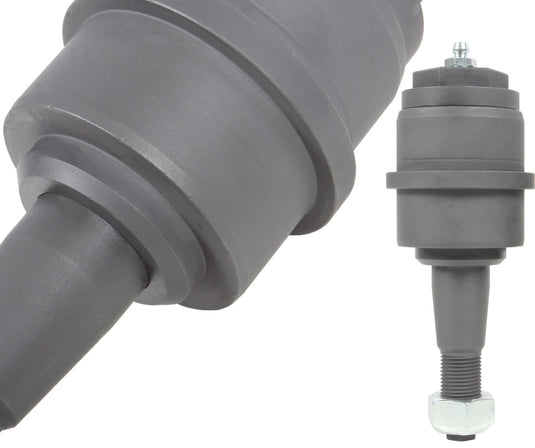

SKU: CS-DUBJ

– Set of Upper Ball Joints

– Copper Plated, Carburized and Dry-Lubed

– Includes a tube of Redline CV2 Grease

– Fitment: Dodge Ram 2500/3500 4×4

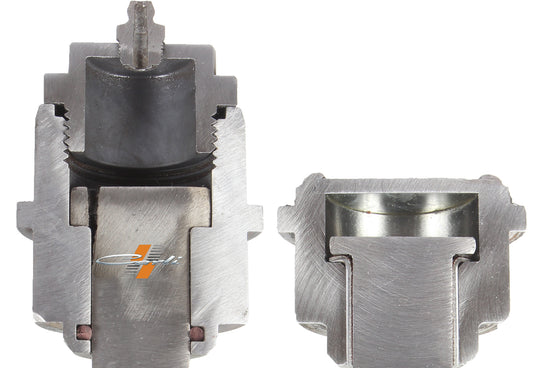

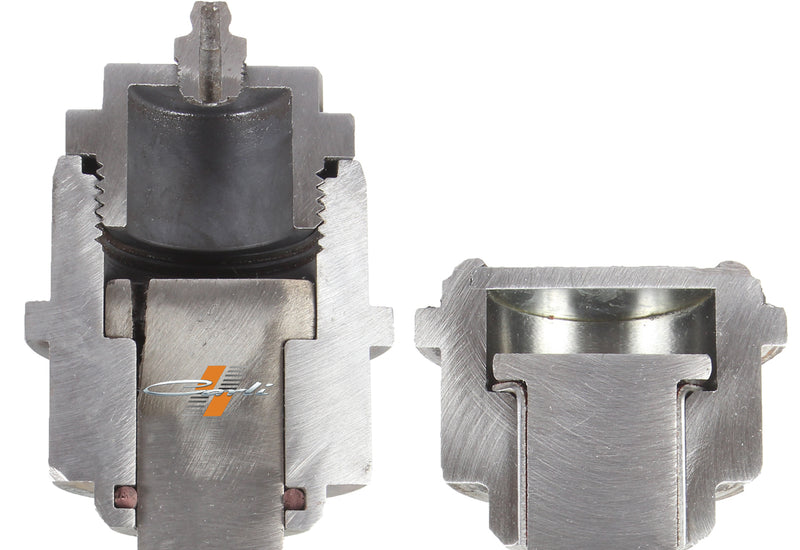

The design comes first. To know how we improved it, let’s take a look at the factory. The Factory Ball Joints are made up of a lower ball joint and upper floating king-pin. What better way to learn a product than to cut it in half to learn it’s functionality. The upper ball joint is designed as a pivot point determining the axis on which the knuckle will move and thus, only sees a lateral load. When you cut into the factory ball Joint, you find a sealed housing, sleeve, pin and boot. The upper cavity stores the grease from the factory and allows the “hat” of the pin to float up and down as the knuckle raises and lowers through the steering cycle. The “hat” of the pin does not make contact with the housing, it only prevents the pin from pulling out the bottom of the housing. As the hat of the pin doesn’t contact, there’s a coated sleeve that isolates the pin from the housing and it’s vertical surface is the only wear surface for the upper.

The Carli Joints are similar in design in that we utilize the same style of a floating King-Pin upper but with several improvements in design. You’ll notice our ball joint has a pin and housing but the “hat” of the pin contacts the housing. This adds a second wear surface to further distribute the load applied laterally to the ball joint while providing the same failsafe as a factory ball joint ensuring the pin cannot be pulled through the bottom of the ball joint housing. Further, there is no sleeve isolating the wear surfaces eliminating the point of failure. The upper cavity’s size is increased to hold a larger grease reserve and the threaded cap both allows access to the cavity and pin if needed and allows servicing through its zerk fitting. You’ll also notice the channel in the pin itself providing a path for grease to migrate to the wear surface. At the bottom of the housing, a Viton Seal prevents the environment from entering the ball joint.

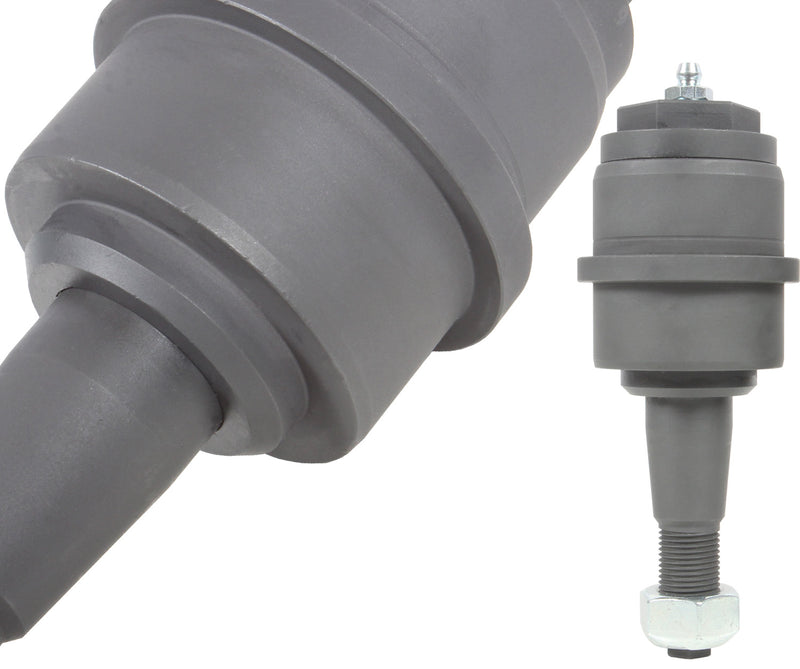

SKU: CS-DUBJ

– Set of Upper Ball Joints

– Copper Plated, Carburized and Dry-Lubed

– Includes a tube of Redline CV2 Grease

– Fitment: Dodge Ram 2500/3500 4×4

The design comes first. To know how we improved it, let’s take a look at the factory. The Factory Ball Joints are made up of a lower ball joint and upper floating king-pin. What better way to learn a product than to cut it in half to learn it’s functionality. The upper ball joint is designed as a pivot point determining the axis on which the knuckle will move and thus, only sees a lateral load. When you cut into the factory ball Joint, you find a sealed housing, sleeve, pin and boot. The upper cavity stores the grease from the factory and allows the “hat” of the pin to float up and down as the knuckle raises and lowers through the steering cycle. The “hat” of the pin does not make contact with the housing, it only prevents the pin from pulling out the bottom of the housing. As the hat of the pin doesn’t contact, there’s a coated sleeve that isolates the pin from the housing and it’s vertical surface is the only wear surface for the upper.

The Carli Joints are similar in design in that we utilize the same style of a floating King-Pin upper but with several improvements in design. You’ll notice our ball joint has a pin and housing but the “hat” of the pin contacts the housing. This adds a second wear surface to further distribute the load applied laterally to the ball joint while providing the same failsafe as a factory ball joint ensuring the pin cannot be pulled through the bottom of the ball joint housing. Further, there is no sleeve isolating the wear surfaces eliminating the point of failure. The upper cavity’s size is increased to hold a larger grease reserve and the threaded cap both allows access to the cavity and pin if needed and allows servicing through its zerk fitting. You’ll also notice the channel in the pin itself providing a path for grease to migrate to the wear surface. At the bottom of the housing, a Viton Seal prevents the environment from entering the ball joint.