The Bean Machine Gridlock Girdle for Cummins Common Rail was conceived out of the need for a very strong girdle that didn’t have a bunch of extra unnecessary parts to it, was lightweight, and did not interfere with the oil pan requiring dents in the pan. We have used other girdles on the market and there were always issues that we didn’t like such as, washer/spacers that were prone to crack and break, studs that hit the oil pan requiring dents in the pan that caused oil leaks, and extra lock nuts that did not like to be used more than once.

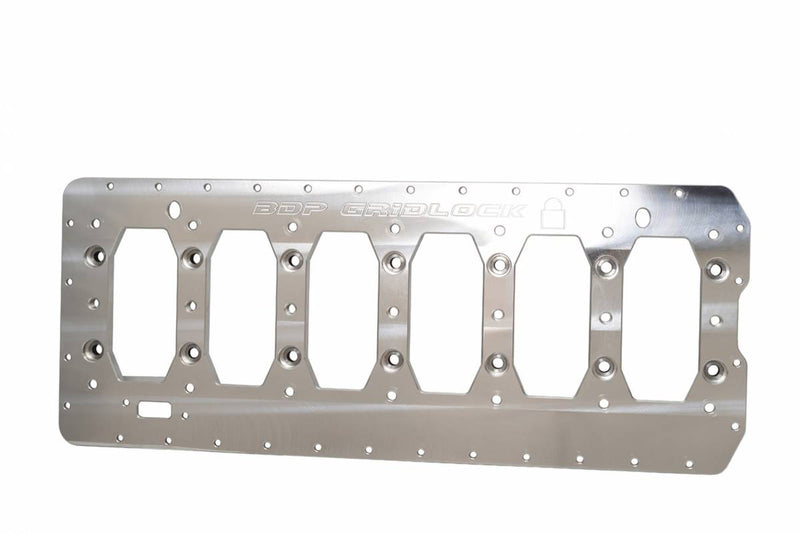

Our girdle system not only fixes the issues stated above, but also increases the strength of the main caps by locking them in place with dowel pins and tying in the entire bottom side of the block by encompassing every available bolt all the way to every edge of the block. To increase the main cap strength even more, preload set screws were added over the center of each main cap. This helps prevent the main caps from bending and bowing under extreme loads of high horsepower engines.

So, what about the aluminum? Why use aluminum instead of steel for a girdle. We first made these out of tool steel. Besides the tool steel making the machine time extremely longer and more tedious, the finished product was ridiculously heavy!

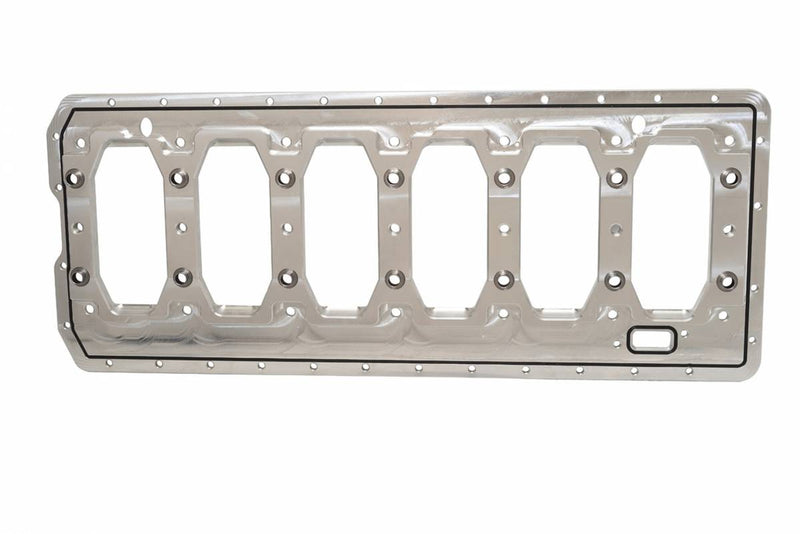

After giving it some thought, why does it need to be a tough tool steel anyway? A girdle system is there to tie the main caps together in order to help prevent main cap walk as well as tie each side of the block together. All of these forces are tensile forces. While tool steels can have 2 times or more tensile strength, the overall thickness of the gridlock girdle more than makes up for the difference. Other girdles on the market are only around .300 of an inch thick, less than half that of our gridlock girdle. This gives the gridlock girdle more than TWICE the tensile strength as the leading competition’s girdle, all this while weighing less. By using pressed in steel inserts at the main studs, we prevent the main stud nuts from compressing the softer aluminum as well as locking the mains in place with a built in locating dowel in those inserts. The girdle is also O-ringed for a perfect seal to the block surface.

Made in Tennessee, USA

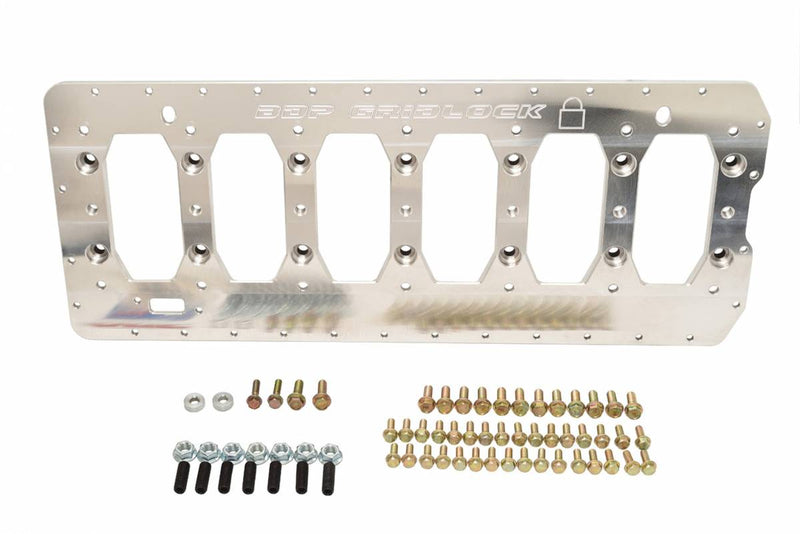

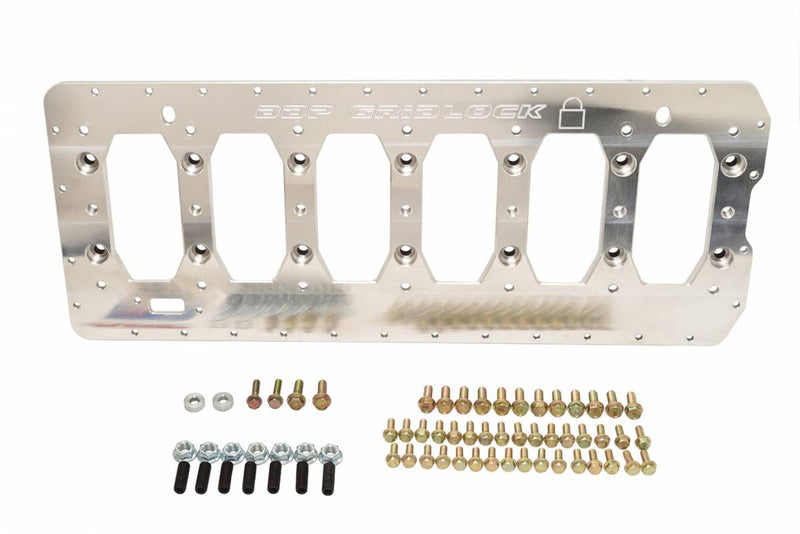

Included in the Kit:

-1 Billet Aluminum Gridlock Girdle with Steel Dowel Pins (1)

-½” x 13 Set Screws (7)

-½” x 13 Flange Nuts (7)

-Oil Pickup Tube Spacers (2)

-Oil Pan Bolts (32)

-Oil Pickup Tube Bolts (2)

-10mm Block Stiffener Bolts (12)

-10mm Extra Long Block Stiffener Bolts For Oil Pickup Brackets (2)

The Bean Machine Gridlock Girdle for Cummins Common Rail was conceived out of the need for a very strong girdle that didn’t have a bunch of extra unnecessary parts to it, was lightweight, and did not interfere with the oil pan requiring dents in the pan. We have used other girdles on the market and there were always issues that we didn’t like such as, washer/spacers that were prone to crack and break, studs that hit the oil pan requiring dents in the pan that caused oil leaks, and extra lock nuts that did not like to be used more than once.

Our girdle system not only fixes the issues stated above, but also increases the strength of the main caps by locking them in place with dowel pins and tying in the entire bottom side of the block by encompassing every available bolt all the way to every edge of the block. To increase the main cap strength even more, preload set screws were added over the center of each main cap. This helps prevent the main caps from bending and bowing under extreme loads of high horsepower engines.

So, what about the aluminum? Why use aluminum instead of steel for a girdle. We first made these out of tool steel. Besides the tool steel making the machine time extremely longer and more tedious, the finished product was ridiculously heavy!

After giving it some thought, why does it need to be a tough tool steel anyway? A girdle system is there to tie the main caps together in order to help prevent main cap walk as well as tie each side of the block together. All of these forces are tensile forces. While tool steels can have 2 times or more tensile strength, the overall thickness of the gridlock girdle more than makes up for the difference. Other girdles on the market are only around .300 of an inch thick, less than half that of our gridlock girdle. This gives the gridlock girdle more than TWICE the tensile strength as the leading competition’s girdle, all this while weighing less. By using pressed in steel inserts at the main studs, we prevent the main stud nuts from compressing the softer aluminum as well as locking the mains in place with a built in locating dowel in those inserts. The girdle is also O-ringed for a perfect seal to the block surface.

Made in Tennessee, USA

Included in the Kit:

-1 Billet Aluminum Gridlock Girdle with Steel Dowel Pins (1)

-½” x 13 Set Screws (7)

-½” x 13 Flange Nuts (7)

-Oil Pickup Tube Spacers (2)

-Oil Pan Bolts (32)

-Oil Pickup Tube Bolts (2)

-10mm Block Stiffener Bolts (12)

-10mm Extra Long Block Stiffener Bolts For Oil Pickup Brackets (2)