SKU: CS-DBJP-03

– (2) Upper Ball Joints

– (2) Lower Ball Joints

– LIFETIME WARRANTY: Register Warranty Here

– Tube of CV2 Grease

– Lower Ball Joint Tool

– Fitment: 2003-2013 Ram 2500 4WD

– Fitment: 2003-2012 Ram 3500 4WD

The main differentiators that matter – materials, process, and design. Our philosophy has always been to skip on the enumeration of materials and process. Leave this to the engineers way smarter than those of us within the organization who are put to the task of trying to destroy the products they design. As our lifetime ball joints have been in circulation for many years and more competition enters the market, the “what makes these so special” questions surfaces regularly; we’re happy to shed some light!

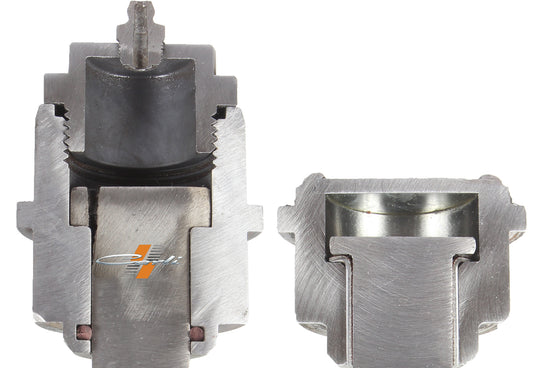

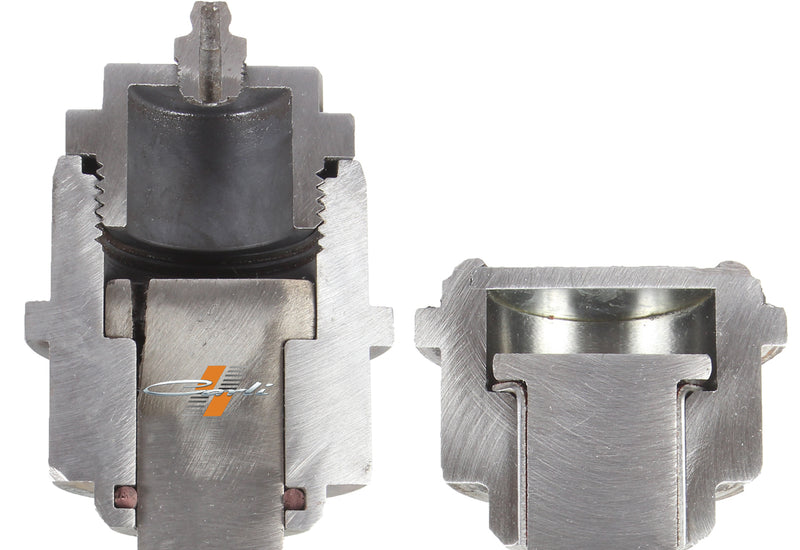

Our improvement on this design begins with the ability to service the joint. The Zerk fitting is recessed into the top of the joint and protrudes at an angle to be aimed forward and slightly inward to allow access to the fitting without needing to disassemble anything. In the cutaway, you can see the channels machined into our ball surface conducive to grease migration. Again, you’ll see no liners of any kind. At the top, a bronze wear surface preloaded by a disc spring, safety washer and snap ring ensures the ball joints wear surfaces are always held tightly together for optimal performance. Not shown in the picture but including in our lower is a rubber seal locking the housing to the pin.

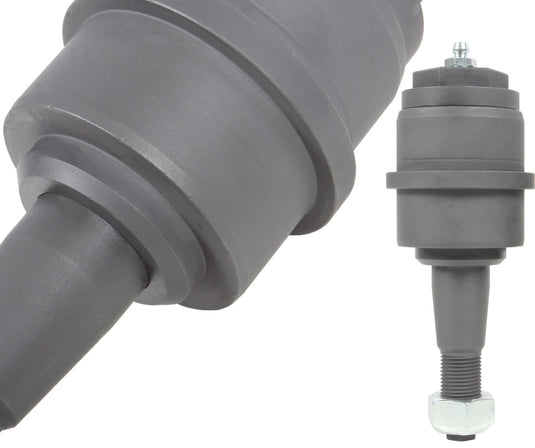

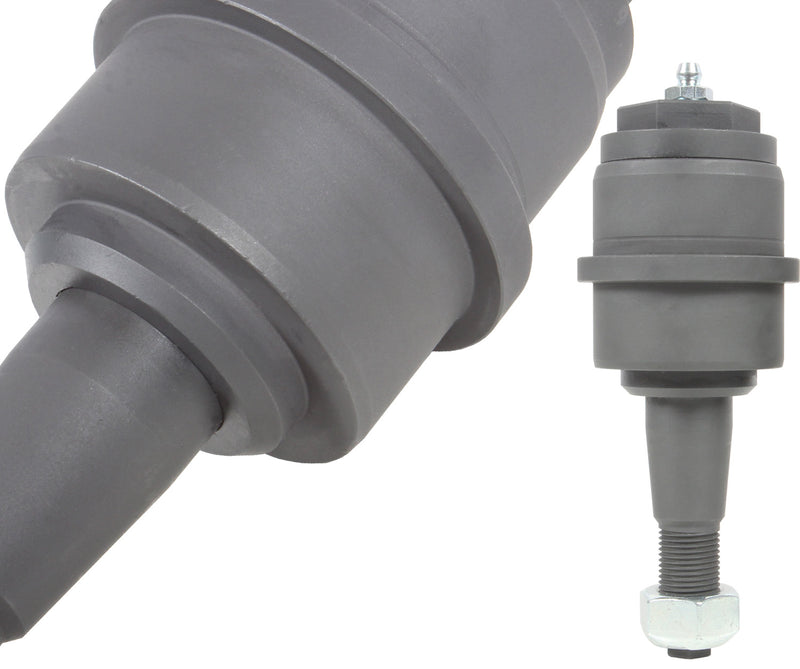

Why are we so confident in the materials that we think we can eliminate wear-surface isolation? We have tested every possible material and process to land where we have since the inception of these lifetime ball joints in 2007. Our process starts with masking. We mask the ball joints, all but the wear surface with a copper plating. Once plated, the ball joints head to carburizing. The carburizing creates an extremely hard surface with a case-hardness (penetrating depth) of 20-25 thousandths. For reference, another process we tried was salt-bath nitride which produced 3 thousandths in a best-case scenario. When the ball joint has completed the carburizing/heat treat, they’re stripped of their copper masking leaving the entire joint heat treated and the wear surfaces incredibly hard. From stripping, they head to dry-lube where the whole joint is coated with a corrosion resistant gray coating to project the joint while the lubricity of the coating pairs with ant seize and Redline CV2 grease to assist in breaking in the wear surfaces.

SKU: CS-DBJP-03

– (2) Upper Ball Joints

– (2) Lower Ball Joints

– LIFETIME WARRANTY: Register Warranty Here

– Tube of CV2 Grease

– Lower Ball Joint Tool

– Fitment: 2003-2013 Ram 2500 4WD

– Fitment: 2003-2012 Ram 3500 4WD

The main differentiators that matter – materials, process, and design. Our philosophy has always been to skip on the enumeration of materials and process. Leave this to the engineers way smarter than those of us within the organization who are put to the task of trying to destroy the products they design. As our lifetime ball joints have been in circulation for many years and more competition enters the market, the “what makes these so special” questions surfaces regularly; we’re happy to shed some light!

Our improvement on this design begins with the ability to service the joint. The Zerk fitting is recessed into the top of the joint and protrudes at an angle to be aimed forward and slightly inward to allow access to the fitting without needing to disassemble anything. In the cutaway, you can see the channels machined into our ball surface conducive to grease migration. Again, you’ll see no liners of any kind. At the top, a bronze wear surface preloaded by a disc spring, safety washer and snap ring ensures the ball joints wear surfaces are always held tightly together for optimal performance. Not shown in the picture but including in our lower is a rubber seal locking the housing to the pin.

Why are we so confident in the materials that we think we can eliminate wear-surface isolation? We have tested every possible material and process to land where we have since the inception of these lifetime ball joints in 2007. Our process starts with masking. We mask the ball joints, all but the wear surface with a copper plating. Once plated, the ball joints head to carburizing. The carburizing creates an extremely hard surface with a case-hardness (penetrating depth) of 20-25 thousandths. For reference, another process we tried was salt-bath nitride which produced 3 thousandths in a best-case scenario. When the ball joint has completed the carburizing/heat treat, they’re stripped of their copper masking leaving the entire joint heat treated and the wear surfaces incredibly hard. From stripping, they head to dry-lube where the whole joint is coated with a corrosion resistant gray coating to project the joint while the lubricity of the coating pairs with ant seize and Redline CV2 grease to assist in breaking in the wear surfaces.