Take full control of your Cummins dual CP3's using your just your ECM. The CP3X2 harness allows you to control your Cummins dual pumps without an expensive dual pump controller.

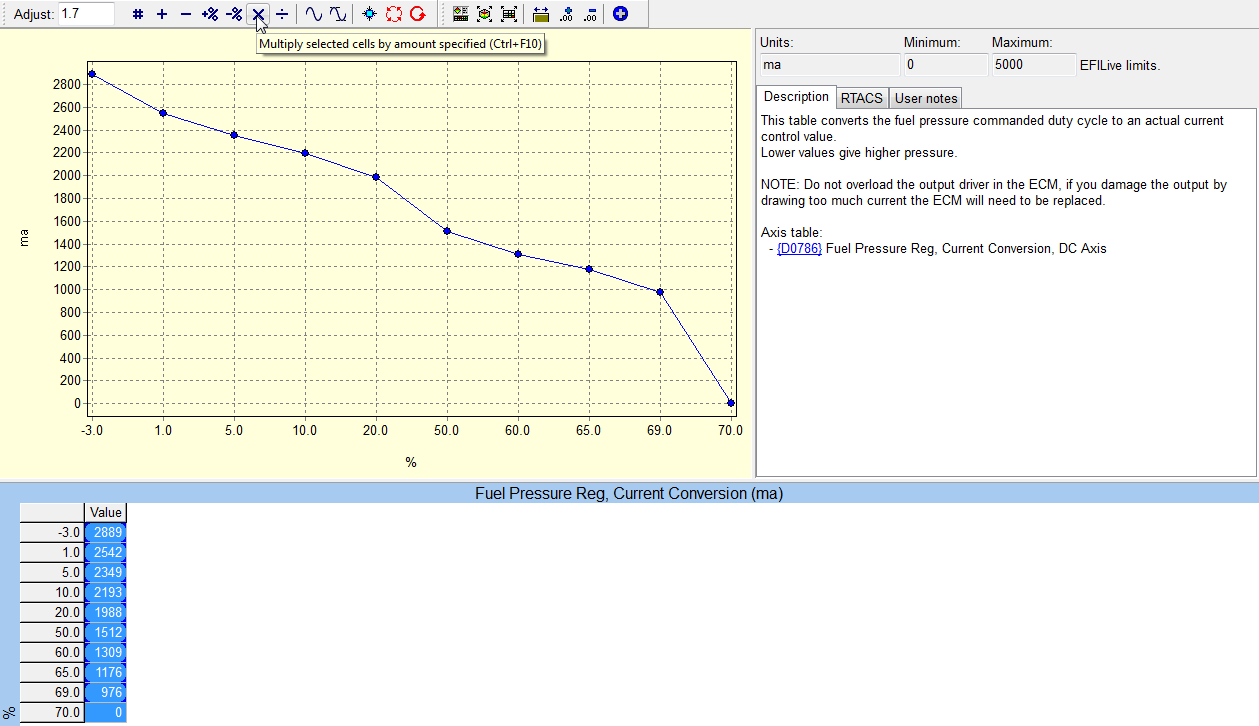

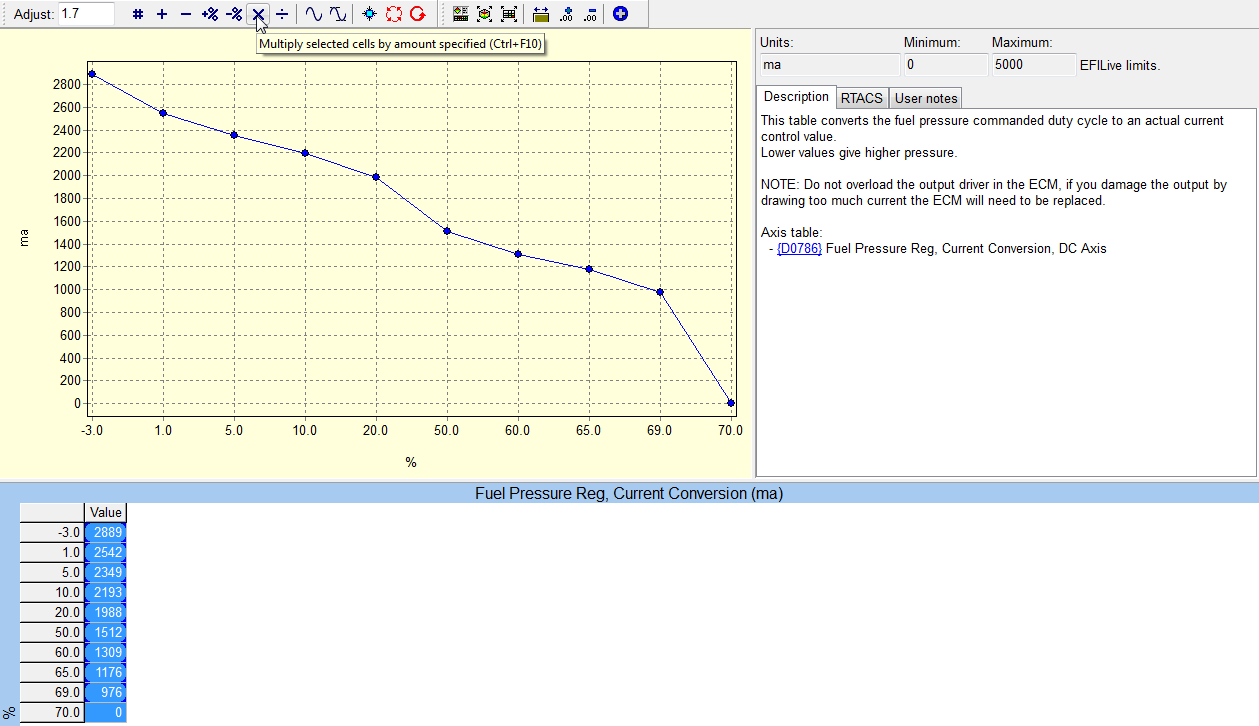

We recommend multiplying the stock FCA current table (D0787) on the Cummins ECM's by 1.6-1.7 as a place to start. The FCA current varies from truck to truck based on the solenoid characteristics, age, and idle lift pump pressure. Higher lift pump pressures at idle will require more amperage at the top of the table (low desired fuel flow) to keep the rail at it's target pressure. If the truck will not start after multiplying the table by 1.7, revert back to the original tune and multiply by a smaller number until the truck starts easily, yet maintains the target rail pressure at idle. This is one of the more time consuming calibration procedures on heavily modified trucks, so make calculated changes, so that you can dial it in as quickly as possible. Once you have the truck idling at the correct target pressure you may need to modify the middle and lower portions of the table to prevent rail pressure overshoot or undershoot. Again, methodical changes in the FCA table will yield the best results. Use the EFILive Scan Tool to log your changes and adjust in the Tuning Tool as necessary. Keep in mind, more current is less flow, and less current is more, zero current being full flow from all pumps. Theoretically you should be able to control 3 pumps. The table will allow the driver to deliver up to 5 amps of current.

Take full control of your Cummins dual CP3's using your just your ECM. The CP3X2 harness allows you to control your Cummins dual pumps without an expensive dual pump controller.

We recommend multiplying the stock FCA current table (D0787) on the Cummins ECM's by 1.6-1.7 as a place to start. The FCA current varies from truck to truck based on the solenoid characteristics, age, and idle lift pump pressure. Higher lift pump pressures at idle will require more amperage at the top of the table (low desired fuel flow) to keep the rail at it's target pressure. If the truck will not start after multiplying the table by 1.7, revert back to the original tune and multiply by a smaller number until the truck starts easily, yet maintains the target rail pressure at idle. This is one of the more time consuming calibration procedures on heavily modified trucks, so make calculated changes, so that you can dial it in as quickly as possible. Once you have the truck idling at the correct target pressure you may need to modify the middle and lower portions of the table to prevent rail pressure overshoot or undershoot. Again, methodical changes in the FCA table will yield the best results. Use the EFILive Scan Tool to log your changes and adjust in the Tuning Tool as necessary. Keep in mind, more current is less flow, and less current is more, zero current being full flow from all pumps. Theoretically you should be able to control 3 pumps. The table will allow the driver to deliver up to 5 amps of current.