Our control arms are a great addition to any solid axle Dodge Ram! These arms are much stronger than the OEM arms, and have more clearance for turning bigger tires.

Unlike OEM, our bushings have a good amount of deflection, and are not prone to failure with increased suspension travel.

Fitment:

- If you have a 1998-2000 model year truck, it's a good idea to check your actual control arm bolt sizes, these can vary by truck production date.

- The 1994-1998 option will have 12mm bolts (the thread diameter not the bolt head wrench size) for the upper arms, and 14mm bolts for the lower. The 1999-2002 model option will be 14mm upper bolts, and 16mm lower bolts.

Details:

- Arms are 1/2" longer in length, allowing the use of 37" tires, even with wheel offsets close to factory specs

- Works on trucks with 0" to 3.5" of lift

- Lower arms are built from high strength 1.5"x3/8" wall 1026 DOM tube

- Upper arms are a solid alloy bar

- Wide flange joints, to make sure bolt torque has no problem keeping the arms locked in place, even under heavy abuse

- Bends in lower arms do not cross center to retain impact strength.

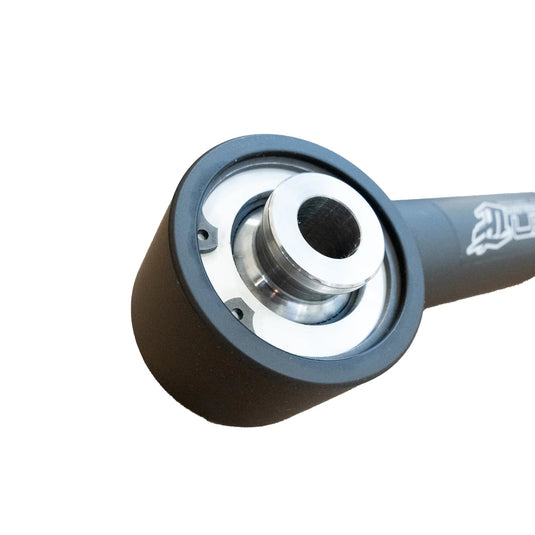

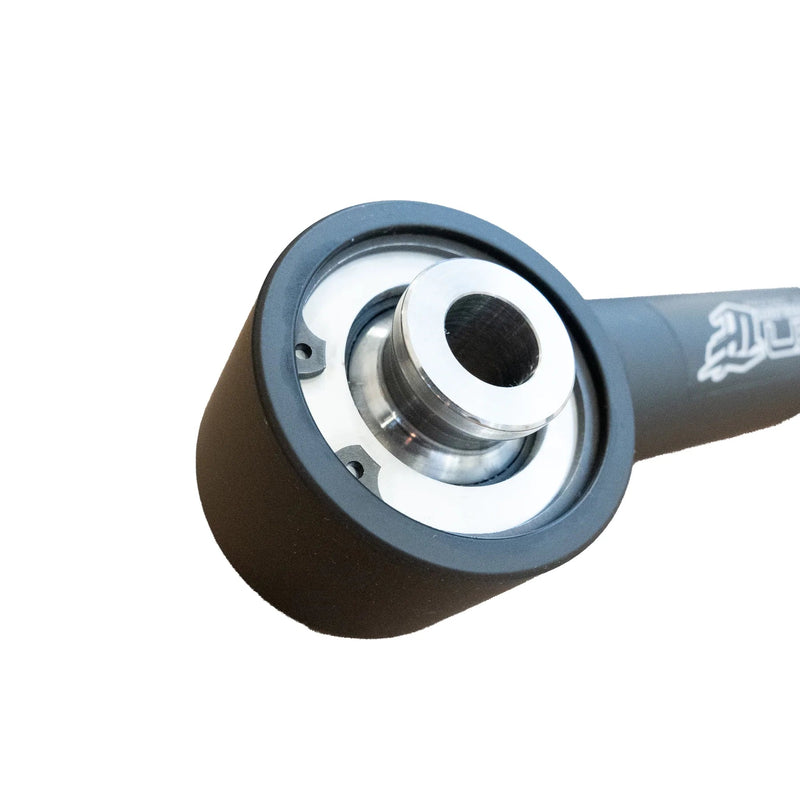

- Machined in house proprietary Self Centering joints to prevent the arms from rocking to one side and rubbing the frame/axle.

- 17-4 Stainless Steel center pivots. 17-4 Stainless is about as hard as a Grade 8 bolt, so these joints will not crush like other brand arms.

- Stainless steel center pivots prevent rust seizing of the bolts and make for easy removal.

- Joints are easy to grease and maintain. No special tools are required it is a very easy and inexpensive job to rebuild when necessary.

- Arms are texture blasted before powder coating, to prevent impact chipping of the coating.

- Main joint bushings are a moderate durometer high quality PTMEG Polyurethane for great wear resistance and vibration control.

We often get people that insist they need adjustable control arms. The only time this is true, is if you are trying to build a custom 4" or so lift, or if you want to run this style arm (short arms) on taller 4" to 6" lifts or so. Problem with both of these scenarios is explained below:

- With 0-3" of lift, you can only make the control arms 1/2" longer than stock. If you make them ANY longer, even 1/8", you will most likely hit the coil mount on the axle against the frame when the suspension cycles. Our arms are already the longest they can be with 0-3" of lift.

- With over 4" of lift, short arms degrade handling and ride quality. Instead of investing in expensive adjustable short arms, put that money into purchasing long arms, and build the truck the proper way.

- Lifts between the 4" and 6" height requires all the same drop components. This means that with a 4" lift you have to limit bump travel 3". This means you increase your bump travel 1" more than stock. Massive waste of potential. For reference, our 3" lifts do not restrict bump travel, so you increase bump travel the full 3" when you lift 3"

Our control arms are a great addition to any solid axle Dodge Ram! These arms are much stronger than the OEM arms, and have more clearance for turning bigger tires.

Unlike OEM, our bushings have a good amount of deflection, and are not prone to failure with increased suspension travel.

Fitment:

- If you have a 1998-2000 model year truck, it's a good idea to check your actual control arm bolt sizes, these can vary by truck production date.

- The 1994-1998 option will have 12mm bolts (the thread diameter not the bolt head wrench size) for the upper arms, and 14mm bolts for the lower. The 1999-2002 model option will be 14mm upper bolts, and 16mm lower bolts.

Details:

- Arms are 1/2" longer in length, allowing the use of 37" tires, even with wheel offsets close to factory specs

- Works on trucks with 0" to 3.5" of lift

- Lower arms are built from high strength 1.5"x3/8" wall 1026 DOM tube

- Upper arms are a solid alloy bar

- Wide flange joints, to make sure bolt torque has no problem keeping the arms locked in place, even under heavy abuse

- Bends in lower arms do not cross center to retain impact strength.

- Machined in house proprietary Self Centering joints to prevent the arms from rocking to one side and rubbing the frame/axle.

- 17-4 Stainless Steel center pivots. 17-4 Stainless is about as hard as a Grade 8 bolt, so these joints will not crush like other brand arms.

- Stainless steel center pivots prevent rust seizing of the bolts and make for easy removal.

- Joints are easy to grease and maintain. No special tools are required it is a very easy and inexpensive job to rebuild when necessary.

- Arms are texture blasted before powder coating, to prevent impact chipping of the coating.

- Main joint bushings are a moderate durometer high quality PTMEG Polyurethane for great wear resistance and vibration control.

We often get people that insist they need adjustable control arms. The only time this is true, is if you are trying to build a custom 4" or so lift, or if you want to run this style arm (short arms) on taller 4" to 6" lifts or so. Problem with both of these scenarios is explained below:

- With 0-3" of lift, you can only make the control arms 1/2" longer than stock. If you make them ANY longer, even 1/8", you will most likely hit the coil mount on the axle against the frame when the suspension cycles. Our arms are already the longest they can be with 0-3" of lift.

- With over 4" of lift, short arms degrade handling and ride quality. Instead of investing in expensive adjustable short arms, put that money into purchasing long arms, and build the truck the proper way.

- Lifts between the 4" and 6" height requires all the same drop components. This means that with a 4" lift you have to limit bump travel 3". This means you increase your bump travel 1" more than stock. Massive waste of potential. For reference, our 3" lifts do not restrict bump travel, so you increase bump travel the full 3" when you lift 3"